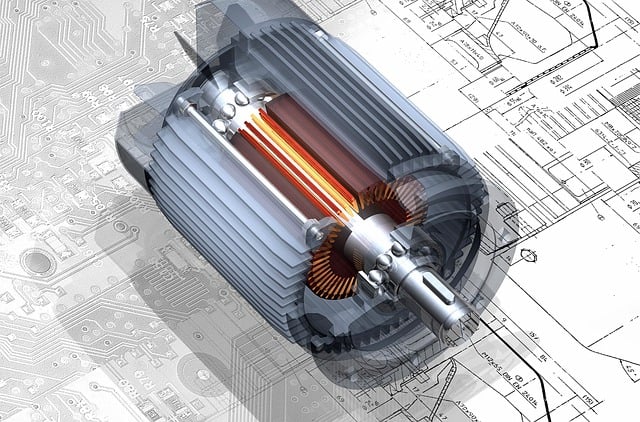

Why are technical drawings still important for sourcing parts?

While 3D CAD files are quite comprehensive in what they can communicate to CNC machines, technical drawings remain important in sourcing parts, as they contain information that a 3D model can’t convey. This includes: internal or external threads, features with non-standard tolerances, and surfaces with specific surface finish requirements.

Even if your design doesn’t include these features, it’s generally good practice to include a technical drawing along with your 3D CAD when sourcing parts. This information is necessary to ensure that parts are manufactured to the required specifications, fit and function correctly, and meet the quality and reliability standards of the final product.

So, how do you prepare a perfect technical drawing for manufacturing? We’ve listed 9 main steps below.

9 steps to prepare a perfect 2D technical drawing

Before we begin, select your template. Standard ASTM, DIN, and ISO templates are available. You can also create a custom template, but ensure that it includes all the necessary details.

1. Add orthographic views

Orthographic views are two-dimensional depictions of your part from different primary views — front, left, right, top and back views. These views convey essential information about your part’s geometry, dimensions, and tolerances. 3D drawings don’t show enough detail — orthographic projections help overcome that problem.

Remember to leave sufficient space to add the dimensions. And avoid excessive use of hidden lines as these can make the drawing confusing and disorganized.

2. Add detail or section views accordingly

In cases where a part is highly complex, contains hidden features, or has challenging dimension, it is good practice to add section views. It is a 2D projection of a part when it is cut through, which enables the manufacturer to visualize intricate dimensions or concealed details (or features) that may not be apparent when viewed externally.

3. Add isometric view (where possible)

The isometric view is a 3D pictorial representation of your part on a 2D surface. It shows your part rotated 45° about the vertical axis, and 35.264° about the horizontal. This view makes it easier for the machinist to understand your part’s geometry and installation direction.