Stainless Steel Bending

Get custom formed sheet metal parts for rapid prototyping and production in as quickly as 3 days.

- ISO 9001:2015

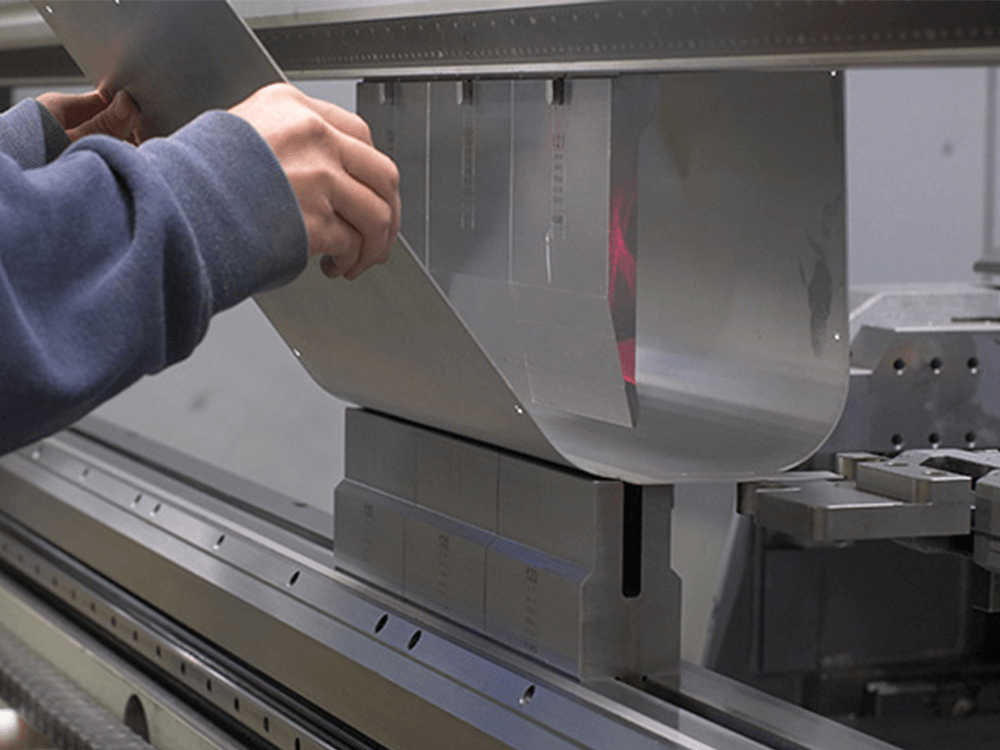

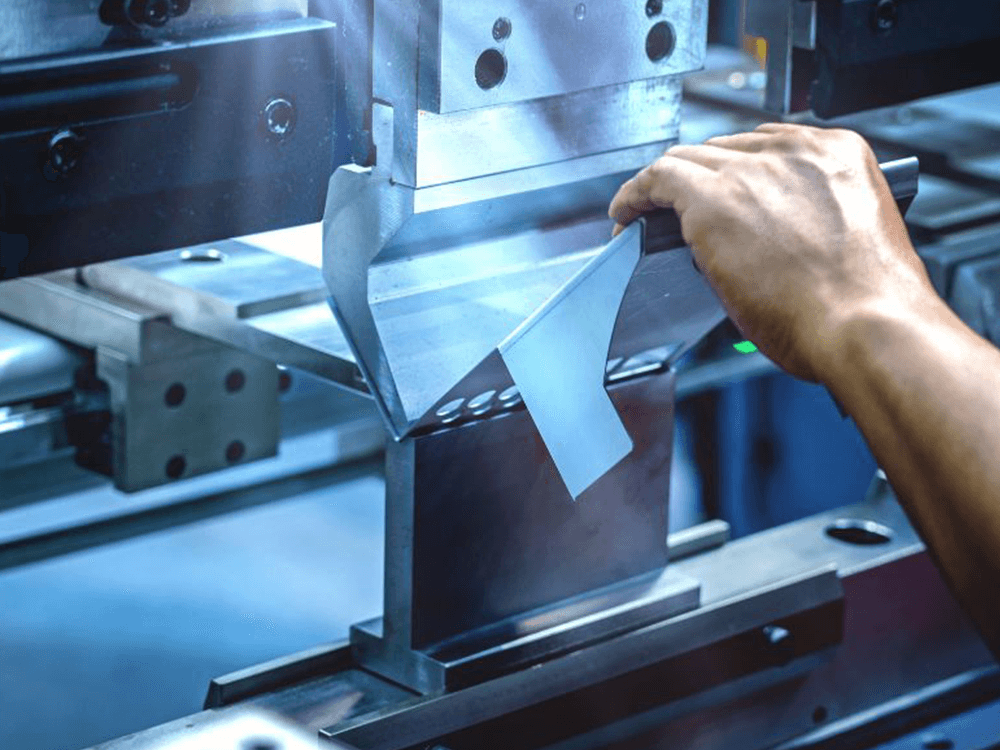

Press brake forming is a metal fabrication process that utilizes a press brake machine to bend flat sheet metal into a desired shape. This process involves applying force between a punch (upper tool) and a die (bottom tool), allowing for the creation of linear bends in various metal materials and thicknesses. To ensure precision and repeatability, all press brakes are equipped with CNC controllers for accurate part positioning. This method is particularly effective for producing components such as U-bends, flanges, channels, and internal bends. Lead times for qualified formed parts can be as short as three days.

Add Your Heading Text Here

In this guide to CNC machining, you’ll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production.

Sheet Metal Forming Design Guidelines and Capabilities

For consistent quality and efficient production times of formed sheet metal parts, please follow these guidelines:

Sheet Metal Materials and Thicknesses for Formed Parts

It is worth noting that the thickness of different metal materials leads to variability in maximum bending capacity

Applications for Press Brake Formed Parts

Press brake forming is a common manufacturing process in the construction materials, food processing equipment, chemical equipment, automotive parts, and energy industries. Common laser cut parts include:

- brackets

- busbars

- covers

- panels

- mounts

- housings

- enclosures

Resources

We stock more than 30 production-grade plastic and metal materials that are suitable for various part applications and industries.

Why are technical drawings still important for sourcing parts? While 3D CAD files are quite comprehensive in what they can communicate to CNC machines, technical

High-density Polythylene (HDPE) HDPE is a resin typically found in pellet form and designed to provide excellent processability for moulders. It is light, affordable and

ypically, metal prototyping tends to be more expensive than producing the equivalent parts in plastic. Considering the purpose of the prototype, it may not always