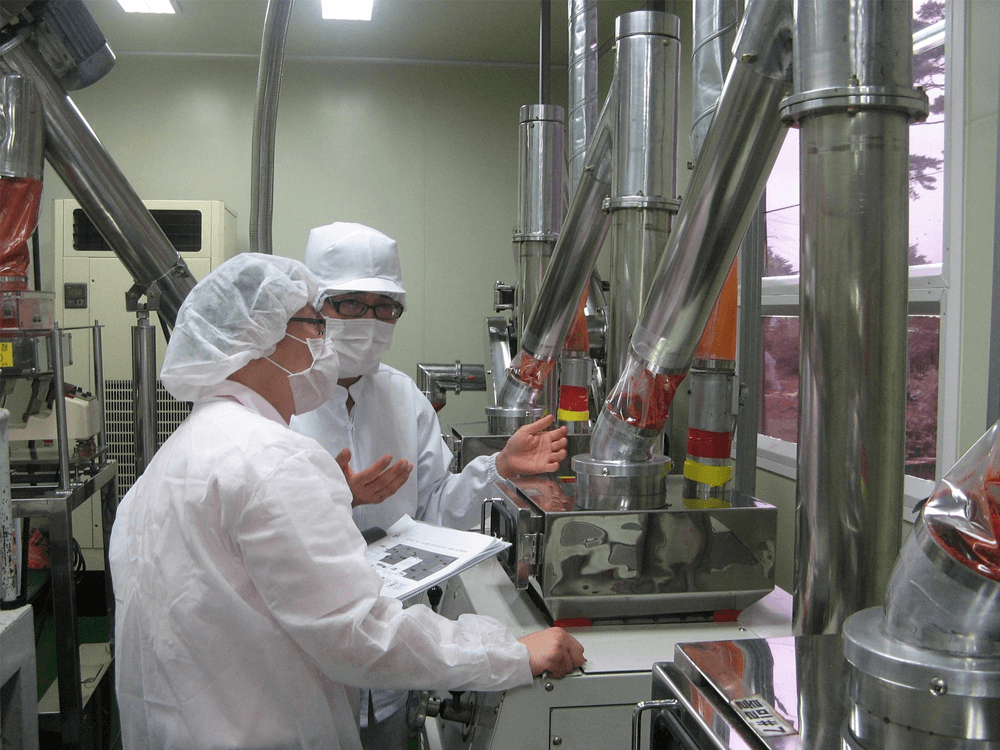

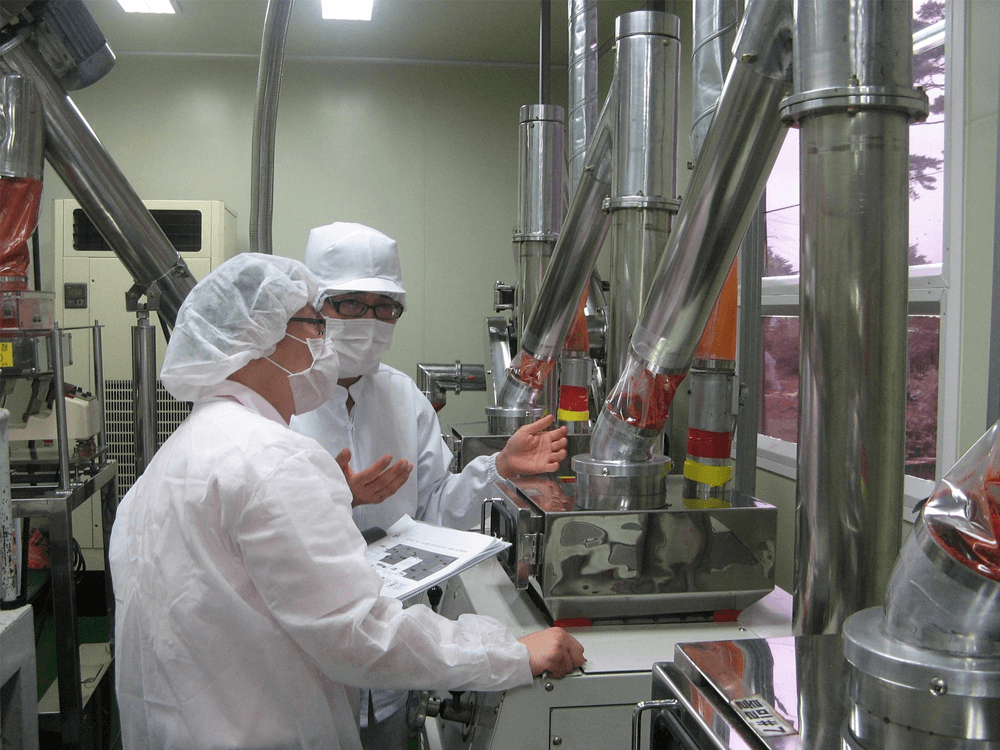

Food Processing and Hospitality

In the food processing and hospitality industries, IWON provide reliable equipment customization and sheet metal component products to quickly respond to market needs and ensure superior equipment performance.

- 35+ surface finishes, 80+ metals

- Instant quotes for 1-1,000 parts

- Lead times from 1 business day

Why Choose IWON for Food Processing and Hospitality

IWON offer reliable prototyping and manufacturing services for food processing equipment. Our expertise and efficient manufacturing processes allow for a quick response to market demands in the food industry, ensuring excellent performance of food processing equipment.

Powerful Capabilities

We have excellent manufacturing capabilities and are ISO 9001:2015 certified, which ensures that our manufacturing processes and quality control are at the height of international standards. This means you can rely on us to provide you with a guarantee of superior quality.

Instant Quote

Our stainless steel sheet metal industry experts will provide you with expert advice on materials and processes to ensure the best solution.

We can meet face-to-face or by phone to answer your questions and respond quickly to your needs.

Fully Customizable

IWON understand the specific needs of the food processing and hospitality industries, so we offer fully customizable solutions, including custom designs and custom tooling features to accelerate part manufacturing and bring flexibility and efficiency to your projects.

Fast delivery times

Our professional engineers have excellent expertise in reducing lead times by up to 50%, ensuring you receive the stainless steel sheet metal parts you need on time to support the smooth running of your project.

Our rapid response in Food Processing and Hospitality

When it comes to construction, our stainless steel sheet metal solutions are custom-made to fit your unique needs. They not only meet but exceed industry standards, and they do so cost-effectively and quickly.

Order Confirmation and Requirements Assessment

Our advanced rapid prototyping services provide an efficient and cost-effective way to create models for rapid testing. At this stage, we offer flexible prototyping solutions to match your specific requirements. By utilizing cost-effective materials and production methods, we bring your near-final product designs to reality. This enables you to inspect and assess the crucial specification details and perform functional testing, all while keeping costs low.

- Customer contact or order receipt

- Confirm customer requirements and specifications

Manufacturing and Production

Our advanced rapid prototyping services provide an efficient and cost-effective way to create models for rapid testing. At this stage, we offer flexible prototyping solutions to match your specific requirements. By utilizing cost-effective materials and production methods, we bring your near-final product designs to reality. This enables you to inspect and assess the crucial specification details and perform functional testing, all while keeping costs low.

- Procure materials

- Manufacture and produce the product

- Quality control and inspection

- Product assembly (if required)

Packaging and Shipping

Our advanced rapid prototyping services provide an efficient and cost-effective way to create models for rapid testing. At this stage, we offer flexible prototyping solutions to match your specific requirements. By utilizing cost-effective materials and production methods, we bring your near-final product designs to reality. This enables you to inspect and assess the crucial specification details and perform functional testing, all while keeping costs low.

- Product packaging and labeling

- Logistics and shipping arrangements

- Product delivery to the customer

After-Sales Service and Feedback

Our advanced rapid prototyping services provide an efficient and cost-effective way to create models for rapid testing. At this stage, we offer flexible prototyping solutions to match your specific requirements. By utilizing cost-effective materials and production methods, we bring your near-final product designs to reality. This enables you to inspect and assess the crucial specification details and perform functional testing, all while keeping costs low.

- Customer confirmation of receipt

- After-sales support and issue resolution

- Collect customer feedback

Trusted by Fortune 500 Companies

- Restaurants and food service providers

- Food packaging and equipment suppliers

- Food Processing Companies

- Kitchen Equipment Manufacturers

- Catering equipment suppliers

- Food packaging companies

- Farm-to-table and organic food producers

- Hotel chains and hospitality groups

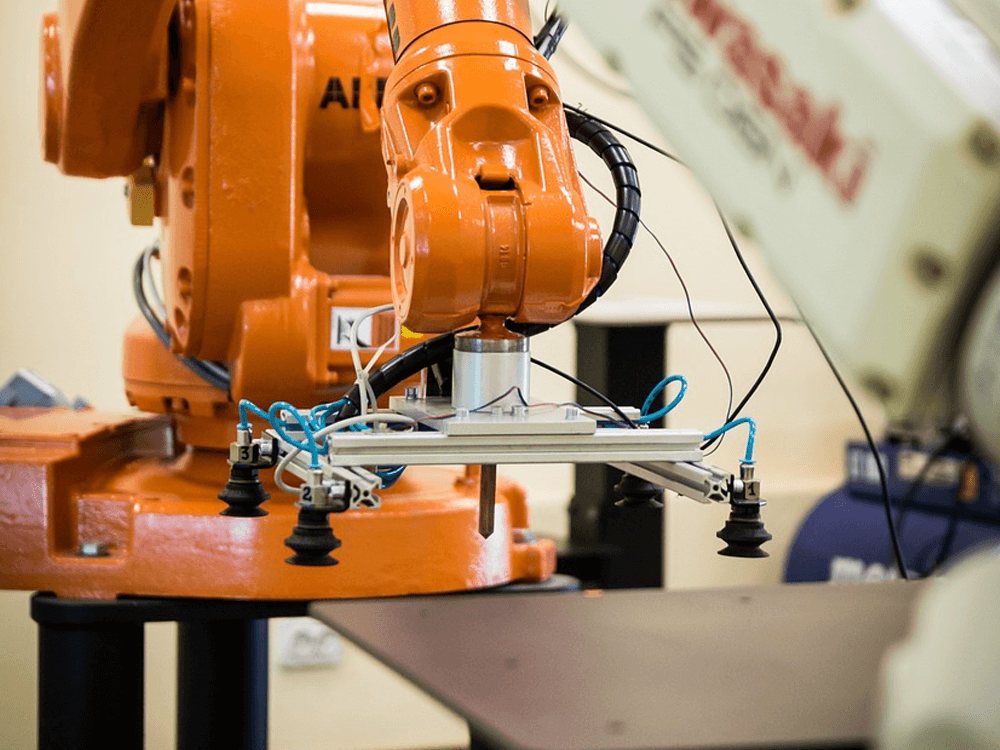

Manufacturing capabilities for Food Processing and Hospitality

IWON utilize advanced production processes and extensive manufacturing capabilities to provide optimal solutions for components in the construction industry. Our team of experienced engineers have years of experience in building materials production, ensuring that we meet and exceed industry standards for durability and performance.

With multiple laser cutting machines running 24/7, we offer our customers excellent technical support, as well as competitive pricing and fast turnaround.

We have a number of bending machines of various sizes, which gives us the ability to manufacture almost any component design, which not only improves productivity, but can also help you reduce costs.

We stand out from most precision metal manufacturers by offering in-house value-added finishing services such as powder coating, anodizing, electroplating, and hot dip galvanizing of metal parts.

Our assembly capabilities range from basic to complex, allowing us to customize the project to your assembly needs. This may involve different methods such as welding, adhesives, rivets or threaded fasteners.

See What Our Customers Say About Us

Customer testimonials hold more sway than a company’s assertions. Explore the feedback from our satisfied customers to see how we’ve met their requirements.

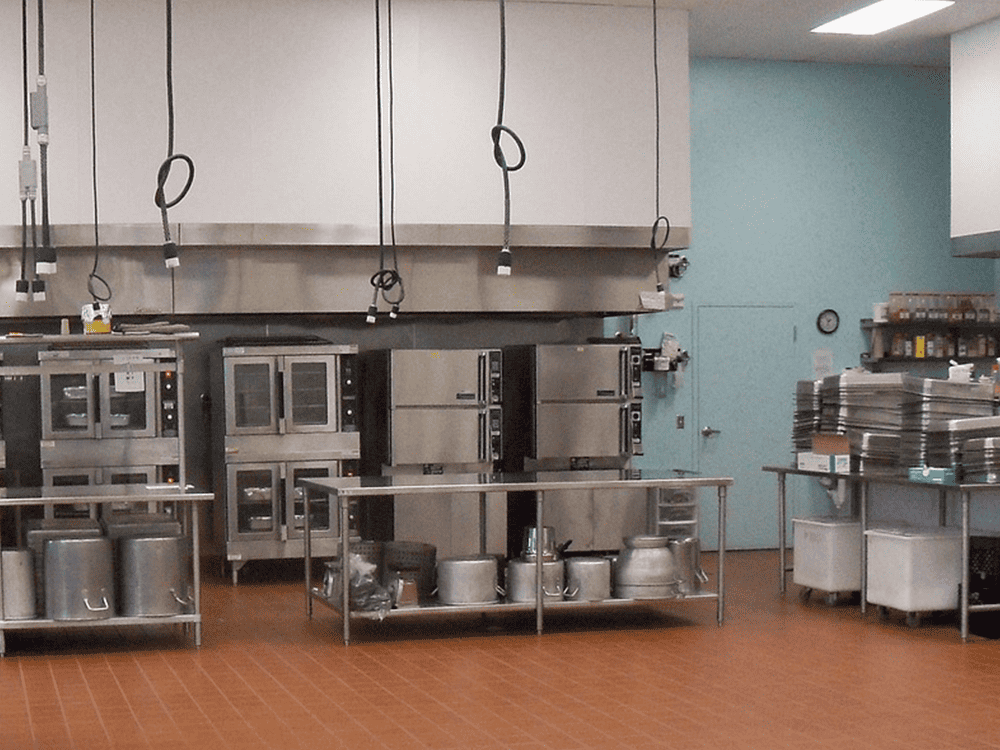

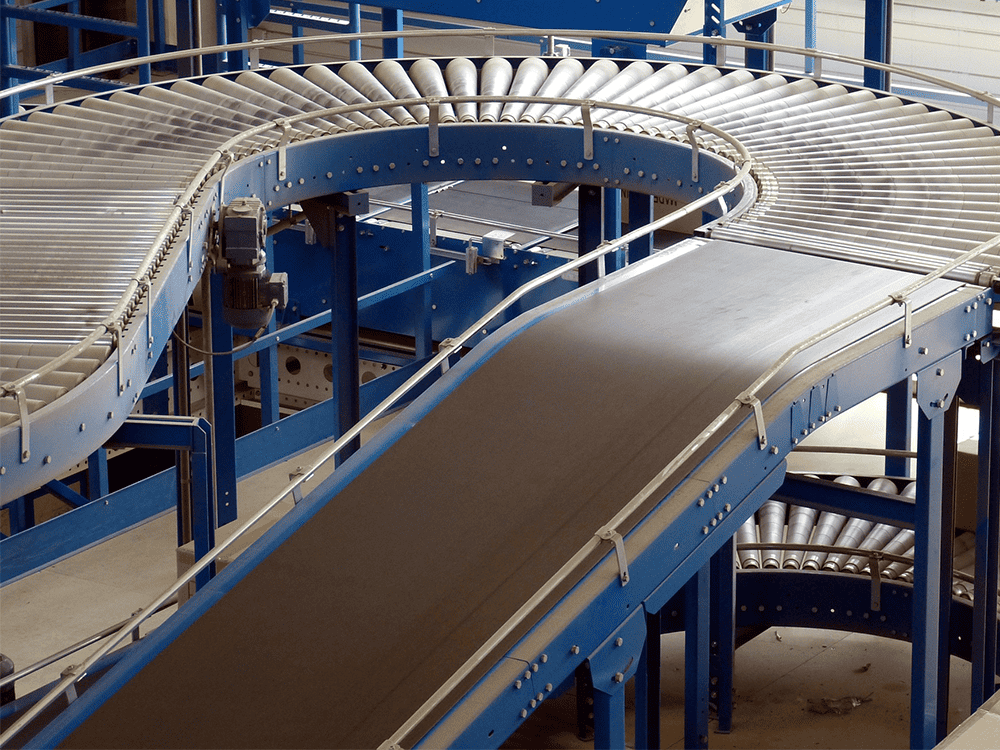

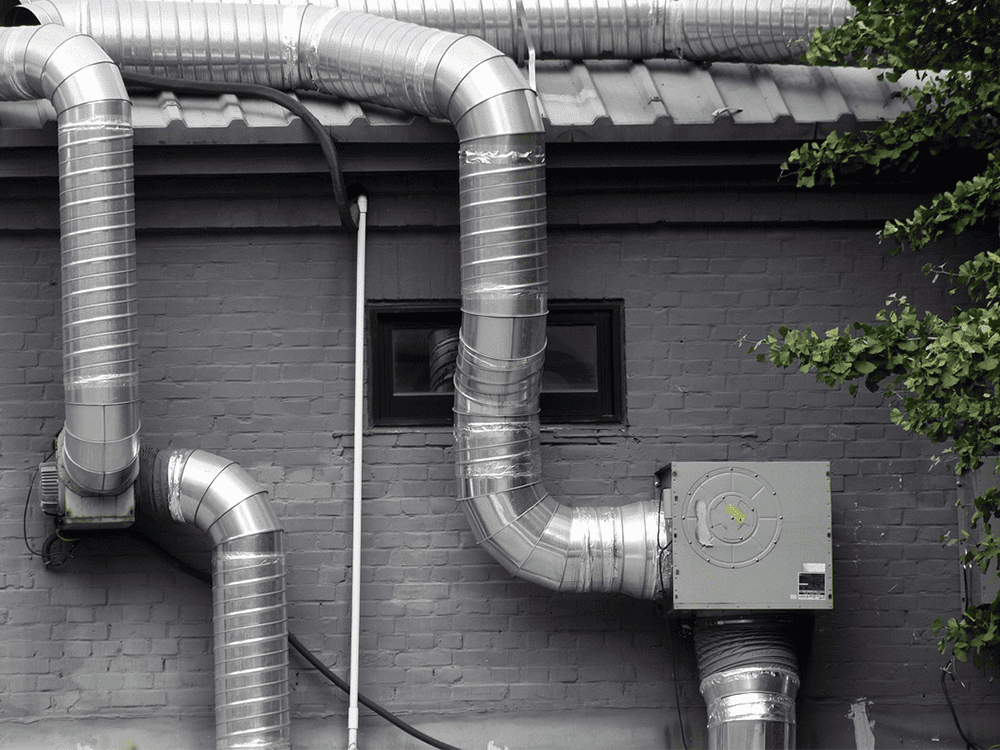

Applications of Food Processing and Hospitality

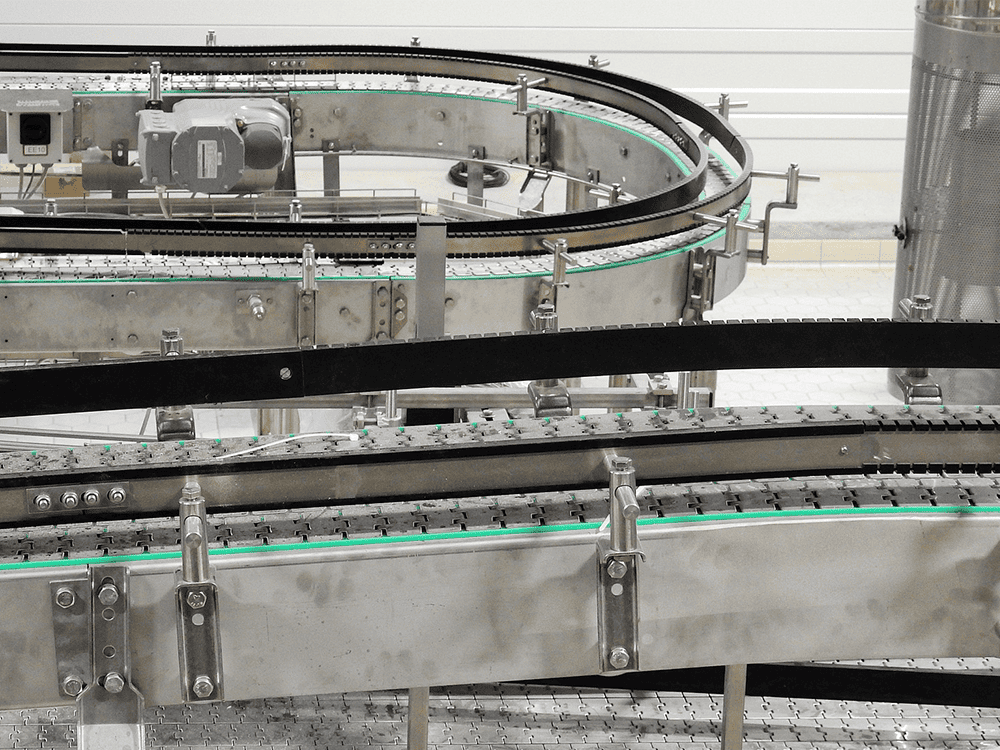

Our team of professionals has many years of experience in sheet metal fabrication and can customize food processing equipment and components according to customer needs. Through our advanced manufacturing techniques, IWON can provide cost-effective services to the hospitality industry in small and large batches.

- Stainless Steel Worktable

- Ventilation Systems

- Vending Machines

- Customized Minimalist Stainless Steel Tables

- Food Store Racking

- Food Tanks

- Food Conveyor Belt

- Food Processing Machine

Prototypes and Parts for Food Processing and Hospitality Companies

Our extensive production capabilities allow us to service many customized equipment solutions for food processing, as well as customized sheet metal solutions for hotels.

Let's Start A New Project Today

Explore More Industries We Support

Energy Production

Manufacturing

Electronics

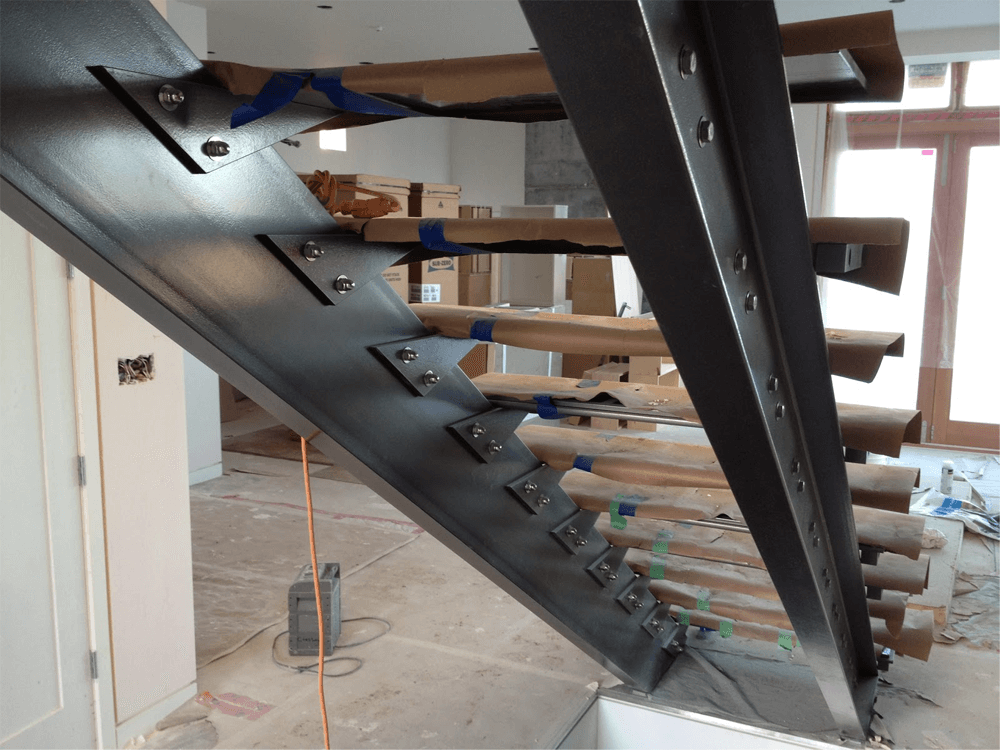

Construction and Building Materials

Explore Related Posts

Why are technical drawings still important for sourcing parts? While 3D CAD files are quite comprehensive in what they can communicate to CNC machines, technical

High-density Polythylene (HDPE) HDPE is a resin typically found in pellet form and designed to provide excellent processability for moulders. It is light, affordable and

ypically, metal prototyping tends to be more expensive than producing the equivalent parts in plastic. Considering the purpose of the prototype, it may not always